At Leech Industries, our precision metal stamping department is built to handle everything from complex, high-volume runs to intricate, low-volume projects across various materials, part geometries, and industries. Our in-house stamping die design, manufacturing, and maintenance capabilities allow us to collaborate closely with OEMs on both brand-new parts and legacy components.

Our team understands that progressive die stamping is an extremely nuanced process that is rarely one-size-fits-all. That’s why we offer flexible solutions to meet our customers’ precise requirements. Allow us to demonstrate the ins and outs of this service—you’ll learn why partnering with Leech Industries yields total confidence in the end product.

End-to-End Precision Metal Stamping Solutions, Under One Roof

Whether you bring us a transfer die or require complete progressive die stamping services, Leech Industries is up to the task. Flexibility is one of the strengths of our metal stamping services across several areas:

Production Volumes

Our shop runs dies at speeds up to 580 strokes per minute, making it possible to produce millions of parts per year. Our highest volume run is approximately 10 million annually! However, in some cases, low volume progressive die stamping is needed. Leech Industries excels in this segment as well, helping customers with their low volume precision stamping in a cost effective manner.

Design

Many precision stamping suppliers focus on flat parts and simple shapes. At Leech Industries, we go further. Our metal stamping expertise includes:

- Coining: Thinning specific areas beyond stock material thickness.

- Deep drawing: Forming complex 3D shapes, such as cups and housings.

- Progressive stamping: creating a complex stamped part with a single die that performs multiple operations at each stroke as the metal moves through the die.

Material Selection

We routinely stamp parts from both standard and exotic materials, including brass, stainless steel, copper, cold-rolled steel, and high-silver-content alloys.

![metal stamping]() Expert Stamping Die Maintenance and Design

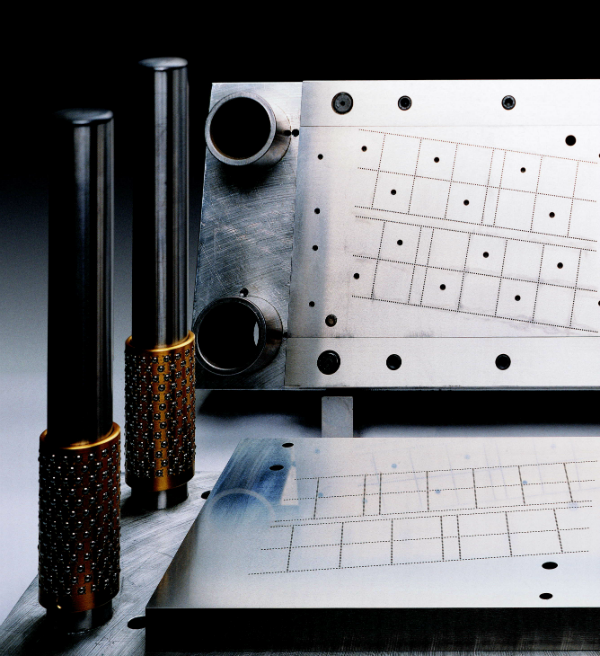

Expert Stamping Die Maintenance and Design

At the core of our stamping services is deep tooling knowledge. As a trusted tool and die shop, Leech Industries not only manufactures new stamping dies but also evaluates, maintains, and optimizes customer-owned tooling. We log every detail of die performance to ensure consistent quality and tool longevity.

Our team can even help you determine if a metal stamping solution is right for your project. In some cases, we’ve guided customers away from stamping when volumes didn’t justify a die build, instead suggesting alternative options as a better match, such as laser cutting with light forming.

Complex Challenges? We’re Confident in Our Solutions

While our customers appreciate our experience, expertise, and versatility, what sets us apart above everything else is our ability to make products that others can’t—or won’t. The team at Leech Industries excels at:

- Stamping extremely thin materials, down to 0.0015”

- Reworking or adapting tools for different materials

- Collaborating with customers on contract manufacturing services that span multiple disciplines, from CNC machining and EDM machining to complex assemblies

As an ITAR-registered, ISO9001 and AS9100 Contract Manufacturer, we understand the stakes involved in challenging medical, aerospace, and defense sector applications. Our expert team meets critical requirements with process control, on-time delivery, and tight tolerances.

Leave It to Leech

From concept to full production, Leech Industries provides more than precision metal stamping processes; we offer comprehensive, end-to-end solutions. Whether you’re in the early stages of product development or looking to scale, our team is here to support your needs.

With the ability to produce custom machined parts, develop, build and run complex progressive dies, and maintain tooling to exacting standards, Leech Industries is a true partner for OEMs that value quality, transparency, and trust.

Need metal stamping done right the first time? Leave it to Leech!

Expert Stamping Die Maintenance and Design

Expert Stamping Die Maintenance and Design