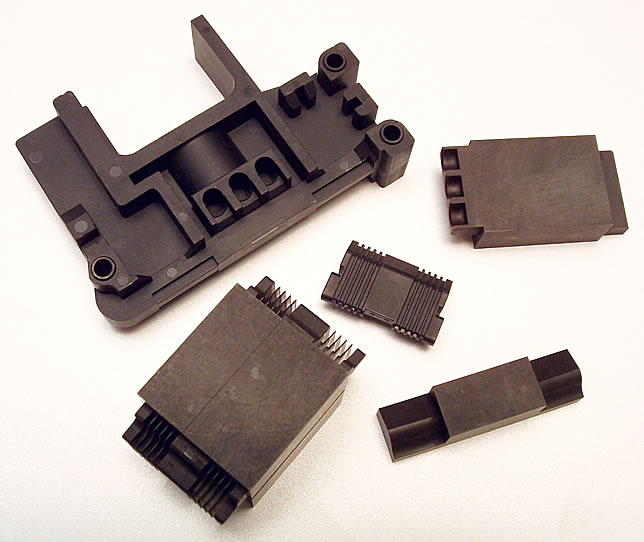

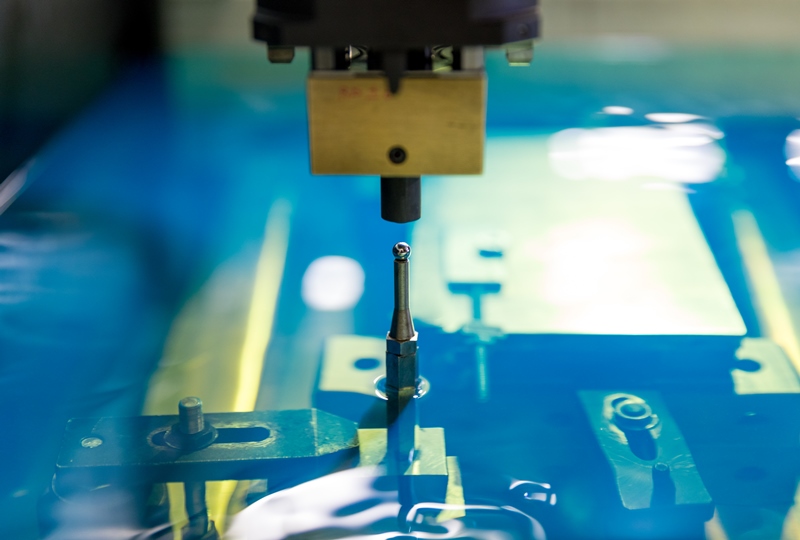

Our Electrical Discharge Machining (EDM) department uses the assistance of CAD, CAM, CNC machining and grinding electrodes made in-house to produce the exact parts you need. Whether your job requires one electrode or multiple, our EDM team can handle it with the use of our Ram/Sinker EDM technology.

Leech Industries offers Sinker EDM services, also called Ram EDM, that produce high-quality, repeatable components. Additionally, we act as a one-stop shop, with capabilities in-house that many other shops do not have.

The Leech team has a comprehensive collection of EDM equipment in our robust contract manufacturing facility. Because we have these machines in-house, we don’t have to outsource any of our EDM machining services. Having all these capabilities under one roof within our facilities ensures that we don’t have to ship EDM parts to outside vendors.

This one-stop shopping approach helps us eliminate the need to ship materials out to a third party. As a result, we can cut down on costs (and pass these cost savings to our customers) and reduce lead times significantly.

Our highly skilled EDM team can handle complex electrodes for applications in industries with the strictest requirements, such as aerospace, automotive, medical devices and more. The top-notch EDM equipment we utilize in-house ensures that we produce complex electrode components with high precision and repeatability.

At Leech Industries, we can run our Ram/Sinker EDM machines lights out. Running lights-out results in:

We can handle each of our services, including Ram and Sinker EDM, from prototype to production. Our engineers support our customers in the design stage, and our operators produce everything from small runs of prototypes to thousands of parts for production.