Leech offers comprehensive plastic molding services for a wide range of industry markets and applications, from medical products to complex electrical components. OEMs across several sectors rely on Leech to deliver high-quality plastic components.

Plastic molding is a highly efficient manufacturing process that creates intricate, detailed parts by injecting molten plastic material into custom molds. Due to its cost-effectiveness, repeatability and consistency, it is commonly implemented to produce a range of plastic components across various industries.

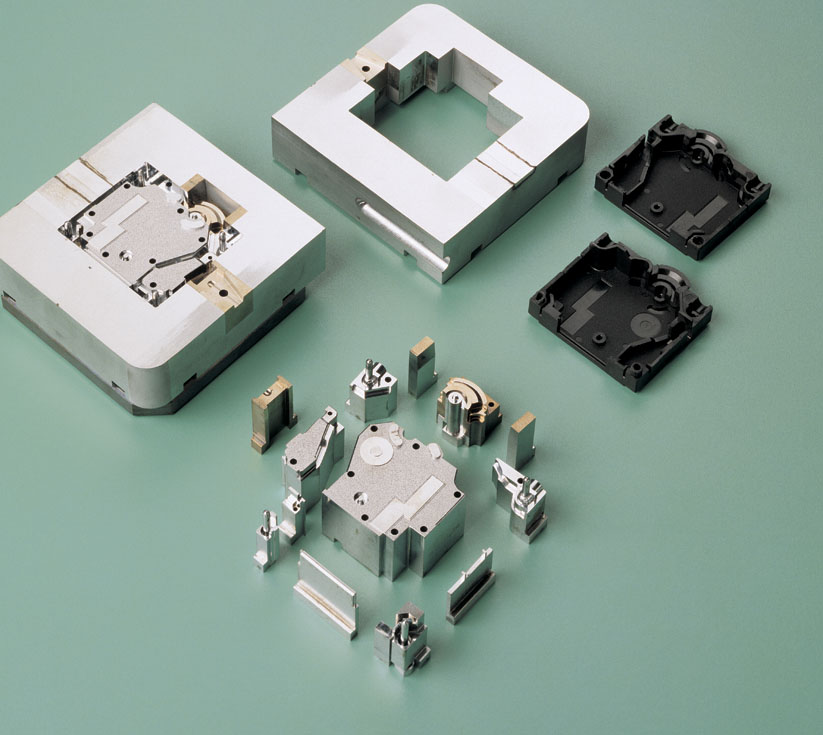

We design, build and run molds to produce parts in the millions, utilizing engineering and commodity-grade resins. We can take on used molds and refurbish, upgrade and retrofit them to bring them back to life and get them back into production.

The typical process for plastic molding at Leech:

Because this process can be easily repeated, injection molding processes are highly capable of producing high volumes.

Thermoplastic molding involves materials that can be melted and re-molded multiple times without degradation, making this process reversible.

The necessary molding technique simply calls for heating the material, injecting the molten plastic into the mold cavity and waiting for the substance to cool before removing it from the mold. This differentiates the process from thermoset molding, which involves an additional “curing” process.

Thermoplastic components are flexible, tough and suitable for a wide range of applications, including consumer products, automotive components and more.

Unlike thermoplastic materials, thermoset polymers undergo a chemical reaction during the molding process that is irreversible, making the molded part unable to be melted or reprocessed.

The process for producing thermoset components involves the initial heating and injection of the material, followed by a curing process. As a result, the cured material forms a rigid, heat-resistant structure.

With notably high heat resistance and durability, thermoset parts are commonly used in applications that require excellent electrical and thermal properties, such as aerospace and electrical functions.

View a list of the materials we work with for both thermoplastic and thermoset plastic molding. For any services we do not handle in-house, the Leech team will outsource this project to one of our trusted vendors. We will project manage the task entirely, ensuring our vendors follow your unique timeline and specifications. As we like to say, “Leave it to Leech!”

Thermoplastic Materials

Thermoset Materials

Related Services

A prototype service is available to assist in product design evaluation and aid in verifying manufacturing capabilities. If you’d like to learn more about this solution, please contact us.