Customers from a wide variety of industries utilize our cylindrical grinding services. OEMs appreciate our high standards for quality and our top-notch customer service. Additionally, customers benefit from working with Leech for cylindrical grinding for the following reasons:

Sometimes, we will move parts from our CNC machines directly to the grinder to get an even closer surface finish. Our grinders can achieve surface finishes as small as four microns; this is better than what a majority of machines are capable of.

In addition to surface finish, our grinders can produce extremely tight tolerances of +/-.00005”. This is tighter than what a majority of our machines can handle.

At Leech, we make our own custom fixtures when we need them for grinding. We have the machinery in our shop to build these custom fixtures that hold our workpieces in place and ensure we are producing the most accurate, precise grinds. We wouldn’t have this capability if we were just a grinding shop, but our variety of fabrication and machining services offers us the versatility we need to craft these fixtures.

Leech Industries offers turnkey solutions for everything from one-off prototypes to large-scale production jobs. Our prototype service is available to assist in product design evaluation and aid in verifying manufacturing capabilities.

No matter how small or large the job, our grinding services can suit our customers’ unique specifications.

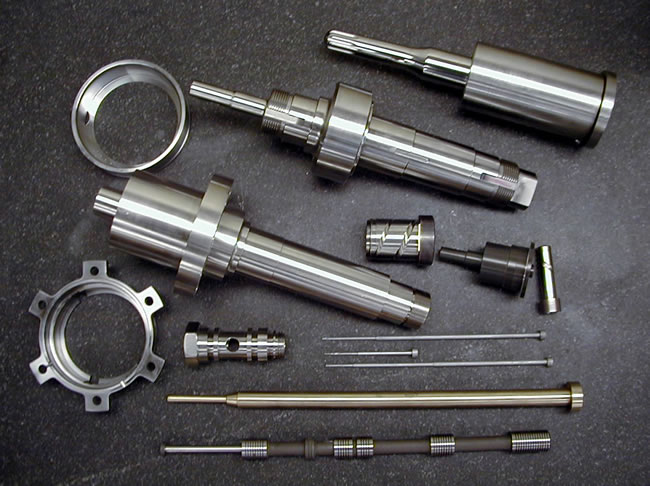

For cylindrical components such as rods, shafts or pipes, Leech uses three different grinding methods:

Leech’s centerless grinding machines can handle materials with outer diameters up to 2”. Our centerless grinders help us produce complex and detailed shapes or forms on workpieces, so we can achieve the tight tolerances required in components that must be ground with intricate geometries.

Our ID grinders can handle workpieces with internal diameters ranging from .0625” to 12”.

Our OD grinding method can accommodate workpieces with outer diameters ranging from .020” to 12”. For larger diameters, it can handle lengths up to 36”, making it suitable for a wide range of cylindrical components.