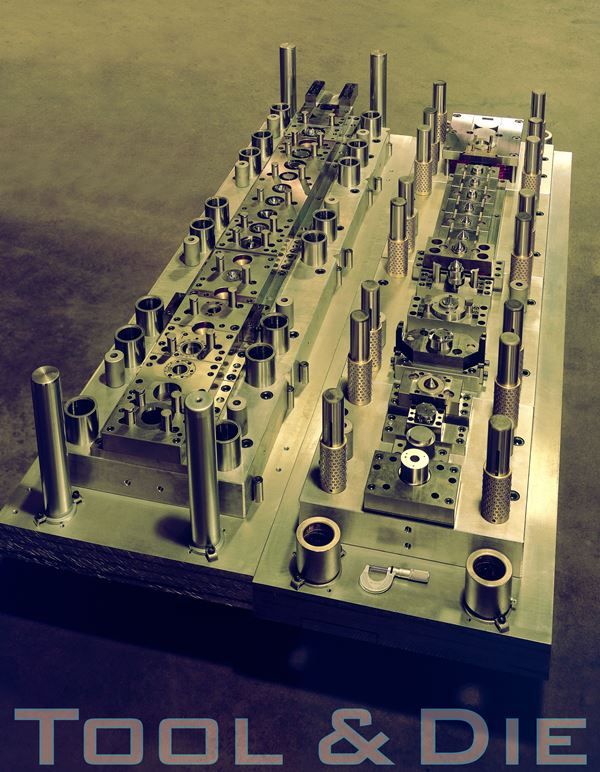

Leech Industries has been in the tool and die business since our business was founded in 1948. Our cutting-edge tool room, as well as our experienced tool and die makers, can machine simple to complex parts while maintaining tolerances of up to 0.00005”. We are equipped to handle projects of all sizes, from one part to millions.

Leech Industries takes our hiring efforts seriously, and as a result, we have a highly effective team. Our technicians have years of experience in a range of functions, including tool and die design and manufacturing. Their expertise combined with their attention to detail results in stellar outcomes for our customers.

Even though Leech Industries has been doing tool and die operations since our business’ inception, we’ve evolved the processes we use, namely our equipment and technology. We utilize cutting-edge technology to achieve tight tolerances, accelerate customer lead times and ensure the accuracy of our tool and die builds. When the end-use application demands tight tolerances, our customers know they can count on us to deliver a fixture that gives them the accurate positioning required for their production run.

At 90,000 square feet, Leech Industries’ facilities are equipped with state-of-the-art technologies and the most up-to-date equipment and machining capabilities. This space offers exquisite tool and die products for our customers.

Leech Industries’ combination of expert technicians, high-end technology and top-of-the-line facilities has cemented our reputation of manufacturing innovation and excellence. Ultimately, our investment in innovation allows us to produce molds and tooling of the utmost quality, priced competitively and backed by exceptional service.

Leech offers customers a one-stop solution for tooling support. Having streamlined in-house tooling operations reduces the need to outsource operations, producing the following results for our customers:

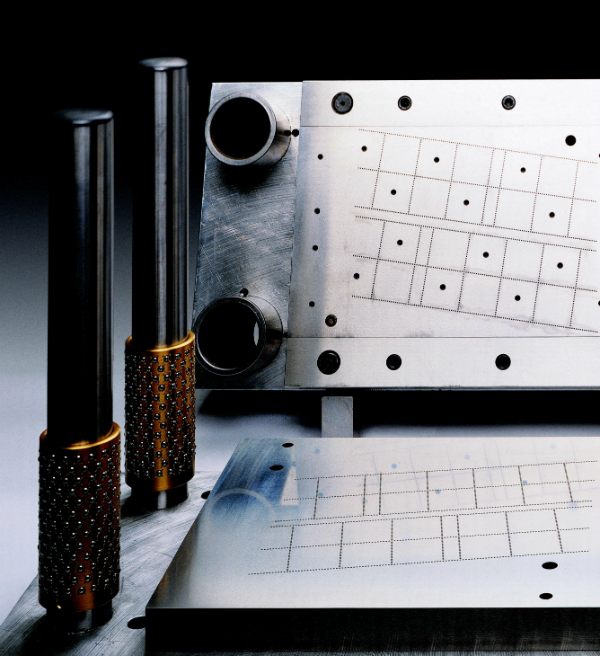

We don’t just handle tool and die – we’re also a plastic injection and die cast molder. This is one of Leech’s main differentiators; our knowledge and expertise in injection molding transfer to our tool and die design and manufacturing functions.

Leech has experience working with the tools and molds we develop, so we are cognizant of the features our own customers experience related to cores and slides, as well as the longevity of the molds.

Leech designs, builds and runs molds to produce parts in the millions for both in-house and customer applications. From consumer products to complex electrical components, customers across a range of industries rely on Leech for the construction of high-quality custom molds.

We specialize in:

**For external customers only

Leech Industries meticulously crafts tools using cutting-edge technology and highly effective machinery. Tooling solutions at Leech include the following: