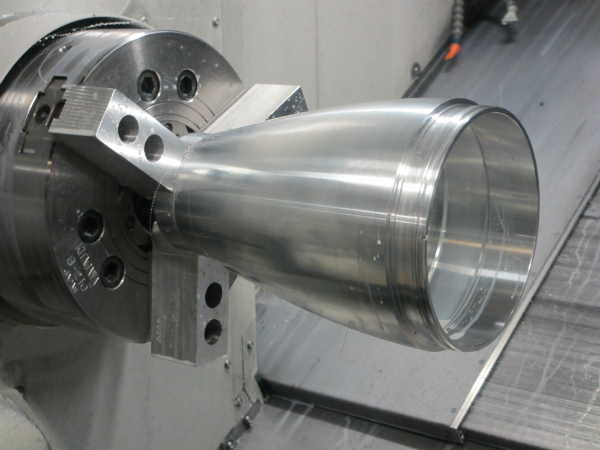

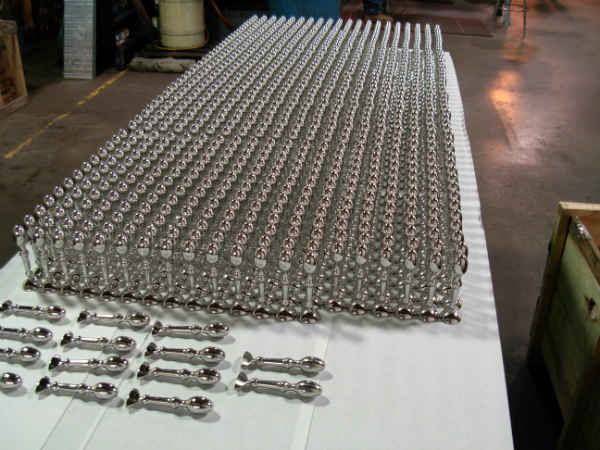

At Leech Industries, we provide precise CNC turning services for a wide range of materials, delivering high-quality, reliable parts for industries that demand the utmost accuracy, such as aerospace, defense, medical, and industrial manufacturing. Our state-of-the-art CNC turning centers can handle everything from low to high-volume production, ensuring your parts meet strict tolerance requirements every time

We specialize in a broad range of CNC turning functions to meet your specific needs, including:

With precision machining and advanced CNC turning technology, Leech Industries guarantees consistent quality, tight tolerances, and exceptional performance.

At Leech Industries, we combine cutting-edge technology with decades of experience to deliver unmatched results. Our skilled technicians ensure your precision machined parts are produced with the highest level of quality and meet your exact specifications, every time.

Contact us today to learn more about our capabilities and how we can support your next project with precision CNC turning services.