Whether you need a single, prototype part or a volume production run, Leech Industries has the team and CNC equipment to deliver your precision, CNC machined part. We offer high-quality Precision CNC Machining Services for a diverse customer base, including clients in the automotive, aerospace, and electronics industries.

With our top-of-the-line equipment and highly skilled team members operating the machines, Leech is capable of handling a range of materials, from standard aluminum and stainless steel grades to challenging materials such as Inconel, titanium, and copper. Here are just a handful of additional exotic materials we expertly machine:

Leech Industries offers numerous benefits to deliver the highest quality, precision machined parts with efficient lead times.

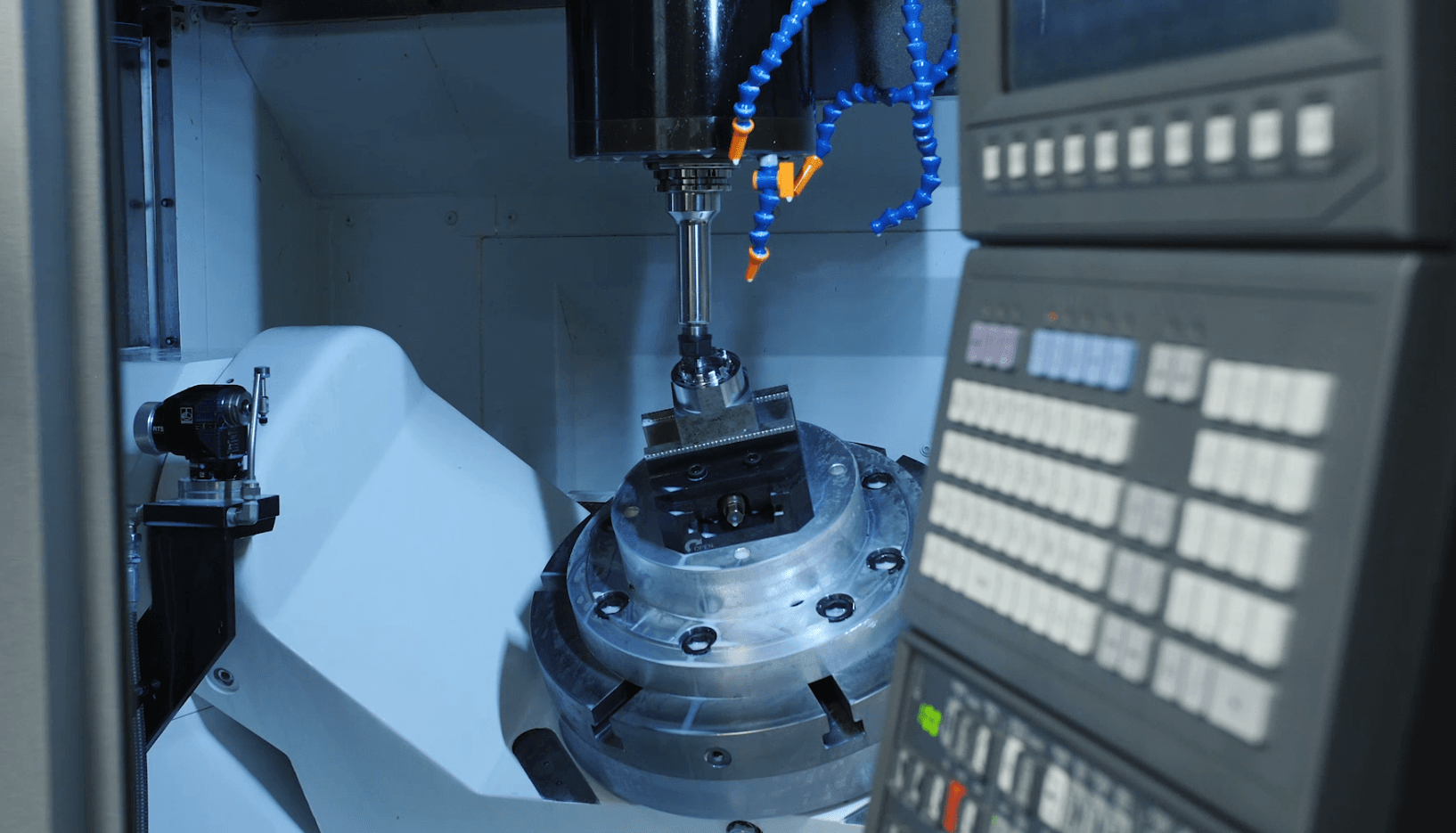

Our advanced CNC Machines provide flexibility, enabling us to complete complex custom machined parts as efficiently as possible. Our equipment capabilities include large tool carousels, pallet changers, part loaders and unloaders, bar feeders, and other productivity enhancements to allow one-and-done production of your precision machined parts.

Utilizing cutting-edge machinery from the most trusted names in precision manufacturing such as Mazak, Okuma, Kitamura, and Grob, Leech can develop manufacturing plans that utilize minimal setups. This approach allows us to hold greater dimensional stability while being inherently more efficient. This translates into higher quality parts and reduced lead times for you, our customer

To maximize productivity and adaptability, Leech Industries has embraced cellular manufacturing. By strategically grouping specific machinery, we optimize operations and streamline production.

This capability is particularly beneficial for our CNC turning services, where we efficiently transition machines into long production runs when necessary. This flexibility improves workflow, minimizes downtime, and reduces lead times, ensuring projects are completed on time.

Leech Industries supports projects from prototype lots to full production runs. Whether producing thousands of parts or fulfilling one-off orders, our advanced CNC Multi-Axis machining centers are equipped to meet your needs.

For low-volume projects requiring expedited delivery, we specialize in quick-turnaround solutions, delivering exceptional parts in just days.

Our state-of-the-art facilities include various CNC machining centers for CNC Turning, CNC Milling and CNC multi-axis 3D machining capable of creating complex, precision machined parts.

Why does this matter? The holding pressure exerted on part, which varies with both part size and machine size, is critical for holding parts securely and machining them effectively. Using the right-sized machine ensures precision and quality in a customer’s machined parts.