Leech Industries has provided contract manufacturing services for customers across a variety of industries since 1948. From the early stages of our business to today, we have built a reputation as a high-quality, reliable source for your manufacturing needs.

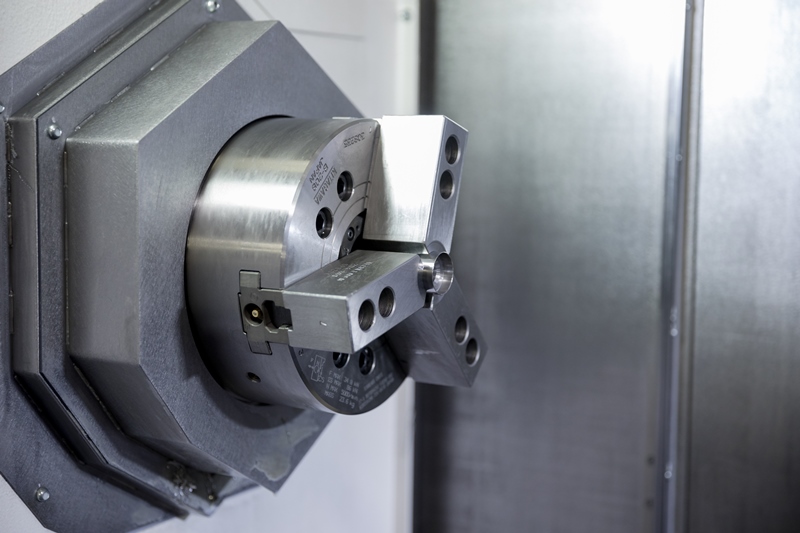

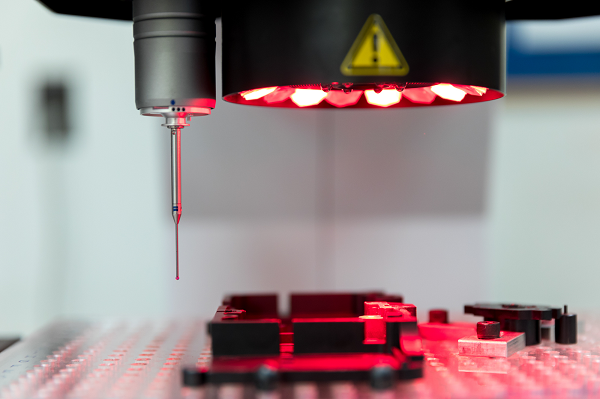

Our 90,000-square-foot facility located in Meadville, PA utilizes industry-leading equipment to ensure the tightest tolerances and optimal productivity. Our highly trained technicians and engineers are experts in each of our services, from design and manufacturing engineering to part manufacturing and component assembly and everything in between.

Leech Industries has made multiple investments in equipment and software to ensure we are best aligned to meet our clients’ needs. Our partnership with Paperless Parts enables us to efficiently and precisely obtain quotes for our clients and proactively address potential risks before the design progresses to the engineering and shop floor. Additionally, our NetSuite ERP system has allowed us to gain a real-time understanding of our processes and improve overall efficiency. These investments in state-of-the-art manufacturing software have improved our capacity and visibility, so we can continue to deliver parts on time, on cost and on quality.

Our investments and capabilities can be fully reviewed in our comprehensive list of equipment.

To improve productivity and reduce waste, Leech Industries has undergone some unique changes to incorporate Lean Manufacturing practices into our facilities and operations. To remain as Lean as possible, we’ve done some restructuring around the shop:

The investment in Lean manufacturing practices at Leech Industries has allowed us to reduce our turn times by 30% over the two-year period. We have been able to pass off time savings to our customers, resulting in lower (and more accurate) lead times, as well as the ability to offer expedited options for OEMs in need of fast turnaround.

In addition to time savings, strategically moving and consolidating operations around our shop to adhere to Lean principles has resulted in:

Working at Leech Industries comes with its fair share of benefits. One of the main perks is our newly renovated, polished office spaces. We took on this renovation project to assist in our recruitment efforts and to ensure our team members have working spaces that allow them to be their most productive. Not only is the space attractive and welcoming, its openness encourages communication and collaboration among teams.

Leech offers full-service manufacturing for a wide range of industries, including: