One of our primary plastic molding services, thermoset plastic molding results in high-quality components that meet tight tolerance requirements and stringent industry demands.

Unlike thermoplastic injection molding processes that are easily reversible, thermoset molding results in a chemical reaction that permanently molds the part. In other words, this process is irreversible.

Compression molding is a molding process where preheated thermoset material is placed directly into the heated mold cavities. The mold is then closed, forcing the material into all cavity areas. Heat and pressure are sustained until the material has cured.

Specific compression molding capabilities at Leech Industries:

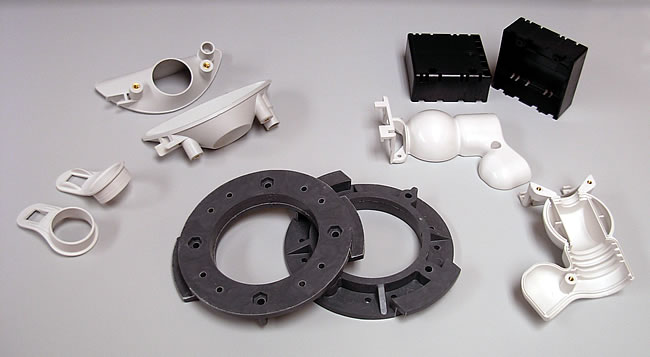

Insert molding and over-molding are additional processes that can be worked into both thermoset and thermoplastic parts.

In insert molding, a pre-formed component (known as the insert) is placed into the mold and molten plastic is injected to surround and bond with the insert. This insert is typically a distinct component, typically either a metal or a different plastic part. Insert molding is often used for adding discrete components within a single part.

A similar process, over-molding involves molding one material (usually a softer or different type of plastic) over another previously molded part to add new properties and enhance the appearance of the original part.

Specific insert molding capabilities at Leech Industries:

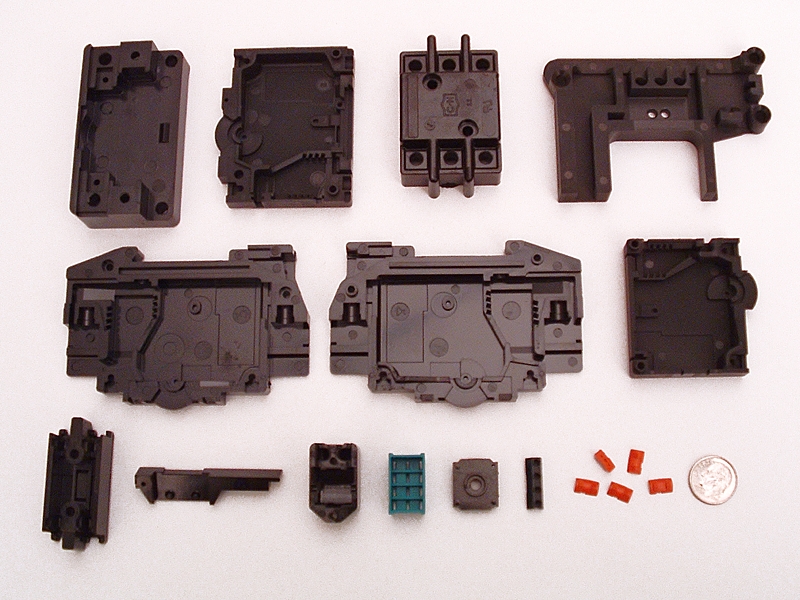

During transfer molding, the material is placed above the closed, heated mold and is forced downward through the gate and into the mold cavities. The mold is held closed while the material cures, resulting in transfer molded parts being cleaner and more consistent than compression molded parts.

Transfer molding is useful in critical applications, particularly those that require tight tolerances or specific materials. In the aerospace and defense industries, where safety and reliability are necessary, this process ensures that molded parts can perform in harsh and demanding environments.

Specific transfer molding capabilities:

Thermoset plastic components exhibit several qualities that make them well-suited for various industrial applications. Here are some key qualities of thermoset plastic components:

If you’d like to acquire prototypes before going forward with your plastic molding projects, utilize Leech’s prototyping solutions to test parts before putting them through to full production. Contact us to find out more.